Support

![]() Do not use rotors and buckets beyond their lifetime in years or cycles.

Do not use rotors and buckets beyond their lifetime in years or cycles.

Rotors and buckets gradually deteriorate with time, total number of uses and actual operating environment such as any damage, deformation or corrosion on the rotors and buckets. There is "Expected Lifetime of Rotors and Buckets in Years or Cycles" for safe operation.

When the rotors and buckets reach the end of their expected lifetime in years or cycles, stop their operation immediately and contact the local distributor or TOMY. The lifetime of rotors and buckets may be shortened in accordance with actual operating environment such as any damage, deformation or corrosion on the rotors and buckets. If any signs of damage, deformation or corrosion are found, stop using the rotors and buckets and contact the local distributor or TOMY.

Expected Lifetime of Rotors and Buckets in Years or Cycles >

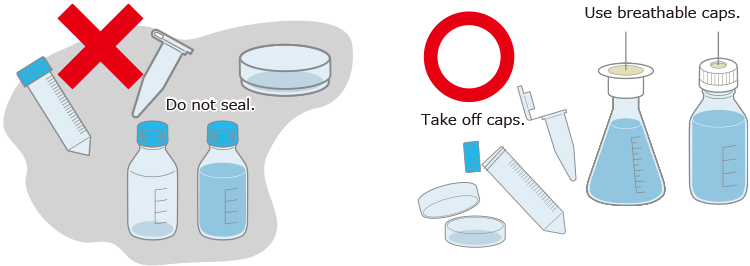

![]() Do not sterilize sealed articles.

Do not sterilize sealed articles.

The pressure inside the bottle or container may increase due to sealing, and the bottle or container may not be able to withstand the pressure when it is removed from the chamber after sterilization, causing it to burst. This can cause burns or serious injury.

In addition, sealing the container can cause sterilization failure.

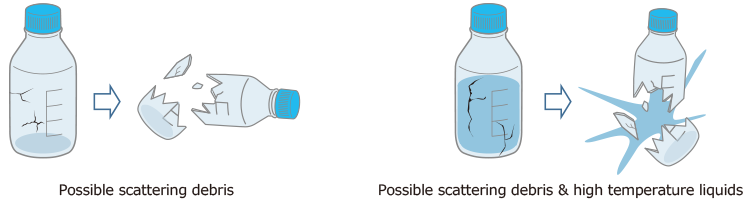

![]() Do not sterilize glass-wares having cracks or scratches.

Do not sterilize glass-wares having cracks or scratches.

It may rupture during removal from the chamber after sterilization, resulting in burns or serious injury.

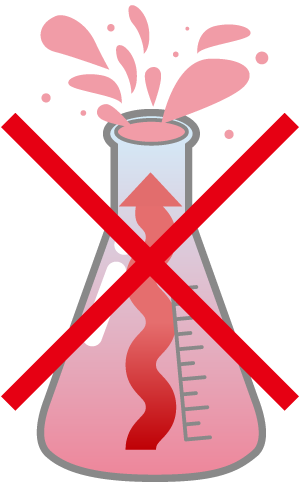

Be careful of high temperature liquids may boil suddenly.

Be careful of high temperature liquids may boil suddenly.

The temperature of liquids falls more slowly than that inside the chamber and may boil suddenly upon impact. Careless handling may cause burns or unexpected accidents.

To prevent burns from sudden boiling and accidents from scattering objects, it is recommended to set the lid interlock release temperature to 60°C and/or to open the lid after the chamber temperature falls to 60℃.

It recently has come to our attention that the system in TOMY’s Ultrasonic Disruptor UD-211 may cause the unit to carry an unexpected electrical charge. This unexpected electrical charge may cause a tingly sensation when the user touches the converter or the metal stand supporting the converter when it is being in use. For this reason, the TOMY Ultrasonic Disruptor UD-211 may pose a risk to users.

If it is currently being utilized at your facility, please stop utilizing it immediately.

For details, please check TOMY Service Notice for Ultrasonic Disruptor UD-211.

The Ultrasonic Disruptor UD-211 has been discontinued.

If you press the “Open” button on the chamber lid of the High Speed Refrigerated Centrifuge Suprema 25 / 23 / 21, but the lid does not open, there is a chance the lifting function of the lid (lid assist function) may be deteriorated or malfunctioning. When this occurs, the chamber lid may feel heavier and more difficult to open. This may lead to the chamber lid quickly closing when you let go of the lid, which could potentially lead to injuries to your hand or your fingers. If you suspect any abnormalities with the chamber lid, please immediately stop your use and contact us.

For product information about High Speed Refrigerated Centrifuge Suprema 25 / 23 / 21, please check here.

Please mount your rack-in-rotor securely for safe operation.

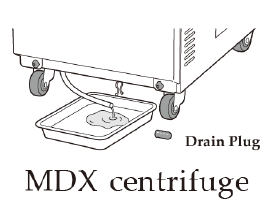

For information on how to mount the rotor on High Speed Refriegrated Micro Centrifuge MDX series, please check To mount the rack-in-rotor on MDX centrifuge.

For details, please refer to the operation manual that came with each model you are using.

For product information about High Speed Refrigerated Centrifuge Micro Centrifuge MDX series, please check here.

TOMY is voluntarily conducting service work for the MX-Series High Speed Refrigerated Micro Centrifuge and TOMY MicroTwin Refrigerated Tabletop Micro Centrifuge.

The voluntary service offering has been initiated due to a report that the chamber lids of certain TOMY MX-Series High Speed Refrigerated Micro Centrifuges and TOMY MicroTwin Refriegrated Tabletop Micro Centrifuge may accidentally open while in use if the rotor rack is not installed into the rotor properly.

TOMY recommends that users refrain from using the above-listed centrifuges until the necessary updates to the centrifuge are made.

For details, please check TOMY Service Notice for MX series and MicroTwin Centrifuges.

The MX-Series High Speed Refrigerated Micro Centrifuges and MicroTwin Refrigerated Tabletop Centrifuge have been discontinued.

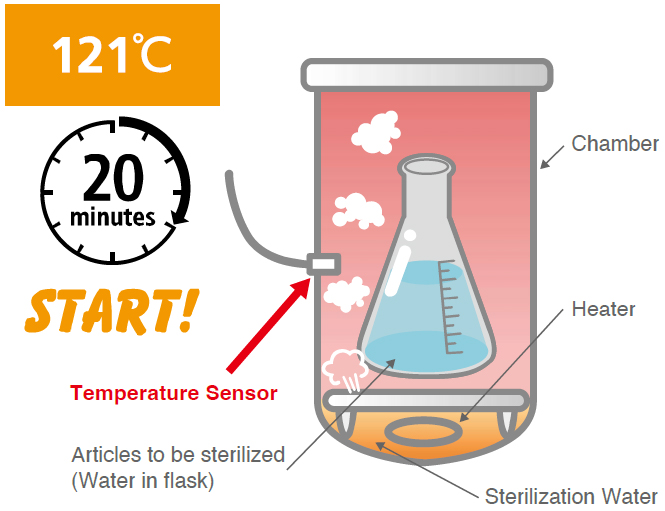

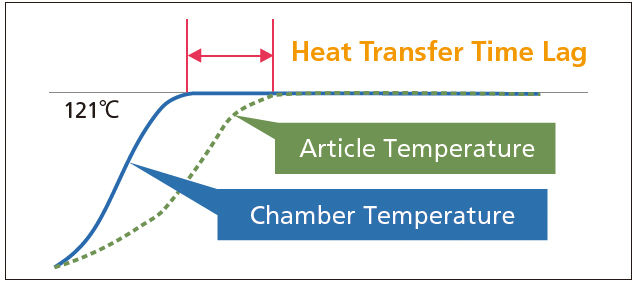

When the autoclave is started, the heater heats the sterilization water, and the temperature inside the chamber rises due to the steam generated. The temperature sensor on the chamber wall detects the ambient temperature of the temperature sensor, which is shown on the control panel display during operation (hereafter “chamber temperature”). After the chamber temperature reaches the set temperature, the sterilization process starts.

The articles to be sterilized are also heated by the steam generated inside the chamber and their temperature rises. The rate of temperature rise varies depending on the quantity, material, shape and accommodation way of the articles to be sterilized. In the sample case shown in the above figure, the more water there is, the longer it takes for the temperature to rise.

At this point, the chamber temperature has reached the set temperature, however the articles to be sterilized may not have reached the set temperature.

This is called “Heat Transfer Time Lag”.

Even if the articles to be sterilized have not reached the set temperature, the sterilization process may start when the chamber temperature reaches the set temperature. This may result in insufficient sterilization and BI test failure. For secure sterilization, it is recommended to add the Heat Transfer Time Lag to the sterilization time.

For details on “Heat Transfer Time Lag” and reference times, check below.

Heat Transfer Time Lag

FLS-1000 >

SX-700 / 500 / 300, SX-700E / 500E / 300E >

For measures of “Heat Transfer Time Lag” for secure sterilization, check below.

External Temperature Sensor

FLS-1000 >

SX-700 / 500 / 300, SX-700E / 500E / 300E >

After using the Autoclave, do you drain the water and clean the chamber?

If samples spilled from culture media or waste remain inside, they will become stuck to the bottom of the chamber and cause clogging the drainpipe, preventing water from flowing smoothly.

In such cases, clear the clog and clean the chamber according to the video instruction.

Draining the sterilization water and cleaning the chamber after each use is a key tip to prevent drainpipe clog and extend the product's lifespan.

For Autoclave preventive maintenance, check below also.

What should we do to clean the Autoclave >

Refer to “Replacing the chamber lid gasket” in the operator's manual.

See the following video additionally with the operator’s manual.

* The chamber lid gasket plays an important role in maintaining air-tightness of the pressure chamber. If any deterioration or damage is found, replace with a new one.

When using Autoclave, the display shows the ambient temperature inside the chamber, but the temperature of articles to be sterilized arrives later than the display temperature. This is called “Heat Transfer Time Lag”.

It is recommended to add the Heat Transfer Time Lag to the sterilization time for more secure sterilization.

For details, please check the Heat Transfer Time Lag test data below.

FLS-1000 >

SX-700 / 500 / 300, SX-700E / 500E / 300E >

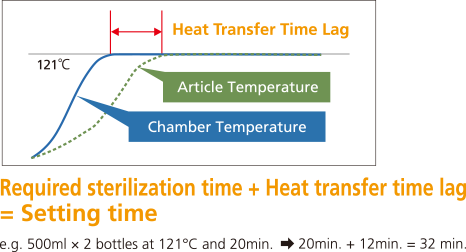

One method is to use the Protector Kit for External Temperature Sensor.

For details, please check the Protector Kit for External Temperature Sensor.

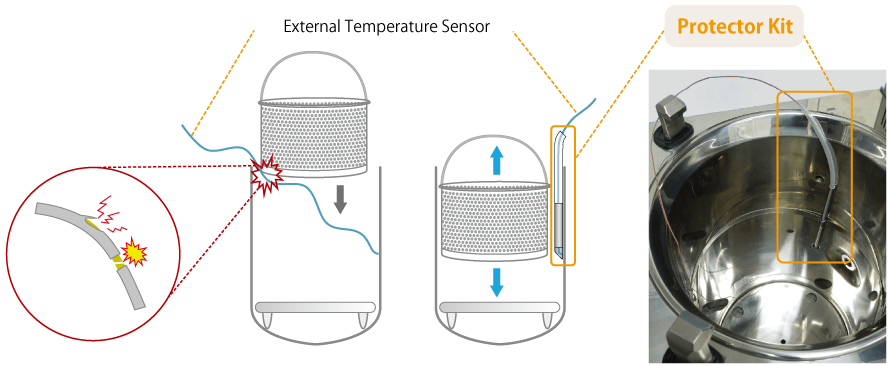

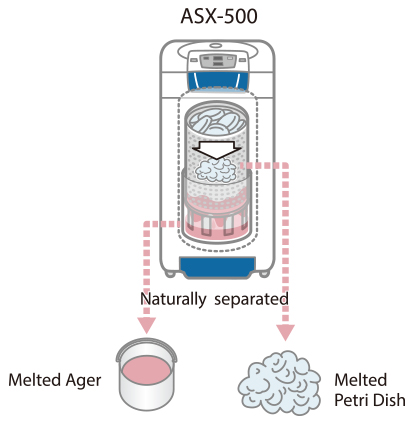

TOMY autoclaves have an optional separator kit that naturally separates petri dishes and liquid during the sterilization process.

![]() Separator Kit for Disposal Petri Dish

Separator Kit for Disposal Petri Dish

Put petri dishes with the medium remained directly into the long basket of Separator Kit.

The medium that melts during sterilization falls into the bucket below, while the petri dish remains in the basket to be separated.

For details, including a video on how to use the kit, please check Separator Kit for Disposal Petri Dish.

If you sterilize wastes daily using sterilization bags, the optional Waste-bin Kit can be used in combination with the bag as if it were a "whole sterilizable waste-bin".

![]() Waste-bin Kit

Waste-bin Kit

For details, please check Waste-bin Kit.

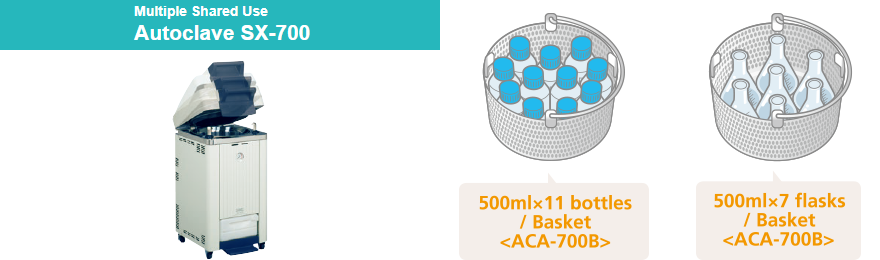

Here are some examples of accommodations for familiar items for each model.

In the case of Multiple Shared Use Autoclave SX and SX-E series, approximately 500ml × 11 bottles or 500ml × 7 flasks can be accommodated. For details, please check Checking the Loading Capacity.

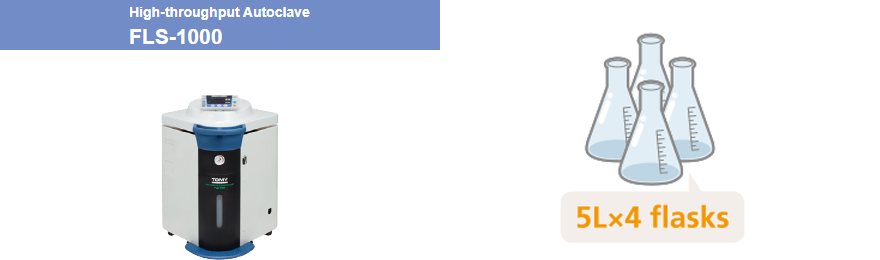

In the case of High-throughput Autoclave FLS-1000, 5L × 4 flasks can be accommodated.

For details, please check High-throughput Liquid Sterilization.

You can also see the video Flask Stand for FLS-1000.

When sterilizing liquids and bottles, please be careful to avoid burns and accidents.

For details, please check SAFETY NOTICE for Autoclave ( Warnings for Sterilizing Bottles and Containers, Cautions for Sterilizing Liquids )

One method is to use a liquid sterilization course to prevent sudden boiling.*

For details, please check Attentive Liquid Sterilization Course.

Please note that it is not possible to completely prevent this depending on the type and amount of liquid, sterilization conditions, etc.

Also, please check the SAFETY NOTICE below.

Cannot be used with standard Autoclaves.

Optional programs for high altitude are available for SX series Autoclaves.

For details, please check High Altitude Sterilization Program.

Disconnect the power supply by switching off the leakage breaker and power supply switch, and unpluging the power plug. Do this when the chamber temperature is sufficiently low.

<Drain water after use>

Drain both sterilized water in the chamber and water in the exhaust bottle / tank after use.

Clean the inside of chamber.

<Clean the inside of chamber>

Gently remove the bottom plate from inside the chamber. Remove contaminants and clean the sinside of chamber using a soft cloth moistened with mild detergent. Rinse detergent and contaminants thoroughly with water and drain water.

Be careful not to distort the sensors in the chamber during cleaning.

<Cleaning the main body>

Remove contaminants using a soft cloth moistened with mild detergent. Wipe off detergent using a tightly wrung-out damp cloth.

For details, please refer to the operation manual that came with each model you are using.

![]() Do not use rotors and buckets beyond their lifetime in years or cycles.

Do not use rotors and buckets beyond their lifetime in years or cycles.

Rotors and buckets gradually deteriorate with time, total number of uses and actual operating environment such as any damage, deformation or corrosion on the rotors and buckets. There is "Expected Lifetime of Rotors and Buckets in Years or Cycles" for safe operation.

When the rotors and buckets reach the end of their expected lifetime in years or cycles, stop their operation immediately and contact the local distributor or TOMY. The lifetime of rotors and buckets may be shortened in accordance with actual operating environment such as any damage, deformation or corrosion on the rotors and buckets. If any signs of damage, deformation or corrosion are found, stop using the rotors and buckets and contact the local distributor or TOMY.

Expected Lifetime of Rotors and Buckets in Years or Cycles >

The Rack-in-Rotor system combines a bucket shaped super lightweight rotor with a variety of drop-in racks made of resin for greater convenience and higher performance.

For details, please check High Speed Refrigerated Micro Centrifuge MDX-310 / 210 / 110

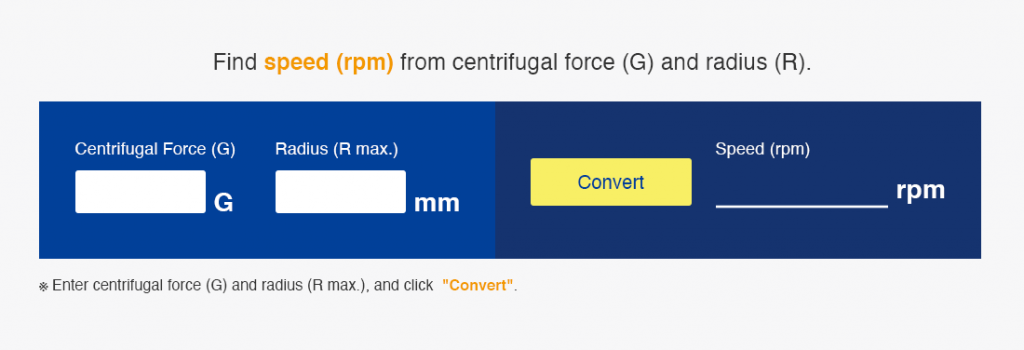

It can be converted between centrifugal force (G) and speed (rmp) with the "Centrifugal G Force Conversion App".

Please try to use it!

Rotor rotating radius is shown on the Rotor Specifications page of the operation manual that came with each model you are using.

Disconnect the power supply by turning off the power switch and unpluging the power plug.

Inspect the chamber for foreign objects such as sample pieces or broken tubes.

Drain the dew condensation water out from the chamber through the drain.

Clean the chamber with a soft cloth moistened with neutral detergent, and then wipe away any detergent residue using a cloth dipped in clean water and squeezed almost dry.

Be careful not to distort the sensors in the chamber during cleaning.

For details, please refer to the operation manual that came with each model you are using.

MT-400 holds up to 1.5 ml x 40 microtubes and provides effective and efficient hands-free mixing.

You can see the video Micro Tube Mixer MT-400.

For details, please check Micro Tube Mixer MT-400.

Please contact us if you need more information.

Inquiry